Performance and History

- Received the Technology 5-Star 5★ rating (HMC)

- Received the certification as a company specializing in materials & components

- Received the Technology 5-Star 5★ rating (HMC)

- Received the certification as a company with Excellent job invention compensation

- Developed Damper Fork

- Received the Technology 5-Star 5★ rating (HMC)

- Received the Technology 5-Star 5★ rating (HMC)

- Excellent Product Development Partner Award (HMC)

- IR52 Jang Youngsil Award (Hybrid Disc)

- Developed Aluminum Knuckle & Carrier

- Lightweight Hybrid Disc New Technology Certification (NET)

- Research institute moved (Dongtan)

- Korea’s first LSJ that minimizes lateral vibration developed

- CJ with excellent rotational balance developed domestically

- Established Seohan Engineering Research Institute (Jincheon)

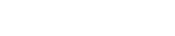

Corporate Organization

-

Research Facilities

Office Building 3,147㎡ / Testing Center 3,150㎡ / Amenities 3,123㎡

Office Building 3,147㎡ / Testing Center 3,150㎡ / Amenities 3,123㎡ -

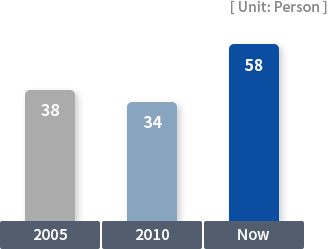

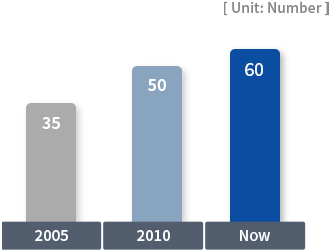

Researchers

-

Research Equipment

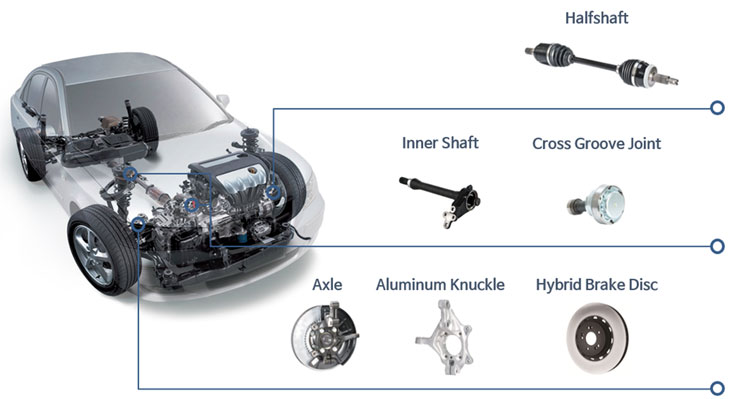

Research & Development Areas

-

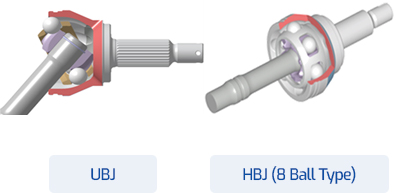

High-Angle/High-Efficiency Joints

UBJ (Undercut Free Joint)

HBJ (High Efficiency Joint)

Increasing outboard angle of bend → Decreasing vehicle turning radius

-

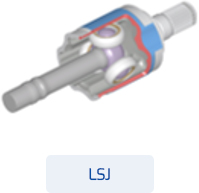

Low Vibration Joints

LSJ (Least Shudder Joint)

Reducing shudder (vehicle's vibration when starting to move) and idling vibration

-

Friction Welding Hollow Shafts

WTS (Friction Welding Tubular Shaft)

Reducing weight compared to solid shafts (30%), improving vibration noise and torsional strength

-

Integral Hollow Shafts

MTS (Monoblock Tubular Shaft)

Reducing weight compared to solid shafts (40%), improving vibration noise and torsional strength

-

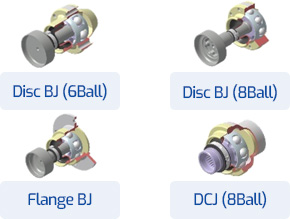

Cross Groove Joint

Propeller Shaft 6Ball & 8Ball

Disc, Monoblock, Flange Type

Lowering heat generation, minimizing backlash, improving high temperature performance, and reducing weight

-

Fixed Joint

6 Balls & 8 Balls for Propeller Shafts

Disc, Monoblock, Flange Type

Improving assembly, improving cut-outs, improving high temperature performance, and reducing weight

-

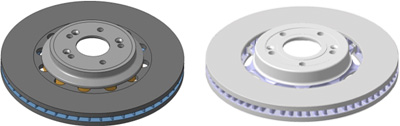

Hybrid Disc

Bonding technologies for dissimilar material casting

Type #1 (Aluminum + Cast iron)

Type #2 (Cast iron + Cast Iron)

-

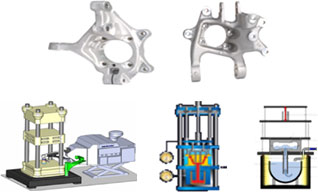

Aluminum Knuckle & Carrier

Casting methods (high pressure, differential pressure, low pressure)

Securing product competitiveness by diversifying manufacturing methods

-

Disc Processing and Surface Treatments

New methods of braking surface processing

New methods of surface treatments

-

Modularization

Axle & Halfshaft, Axle & Brake complete, Integrated Axle

Improving system performance

New system structures

Achievements of Research

-

109Patents registered in Korea

109Patents registered in Korea -

9Patents registered internationally

9Patents registered internationally -

33Domestic and international applications

33Domestic and international applications -

3Designs

3Designs